I’ve tried to report the issue to Prusa support but they keeps trying to diagnose it as user error. But at this point I’m at a loss and presume that it’s either a firmware issue or a sensor issue on my unit.

Either way im very disappointed.

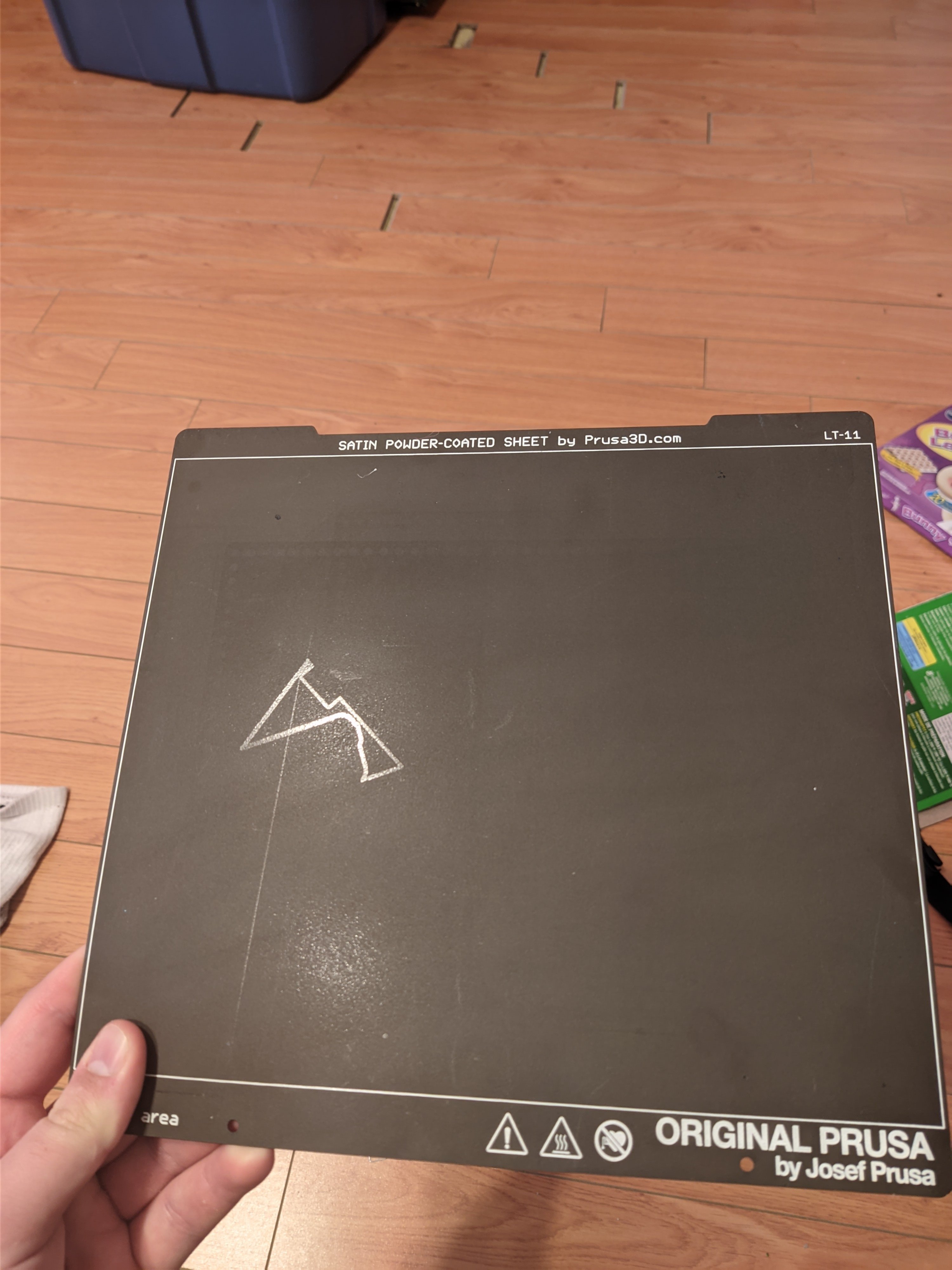

And before you ask, this is the opposite side

EDIT: I will note that this print sheet is ruined for my use case, since those patterns will be shown on the underside of my prints. But the print surface still works and can be used without issue… if you ignore the gouges that are being detailed into every print.

I just had to read up on the MK4 because I don’t own one. Apparently this machine uses a load cell on the bed to detect the nozzle touch? That means that to home Z or mesh level the bed, the nozzle has to touch the build surface. This strikes me as a rather bad idea. I can think of tons of situations such as a pointy diamond or ruby nozzle, a very hot nozzle, or a nozzle with hardened crud stuck to it all causing damage to the print sheet, not to mention the potential for damage to the nozzle itself.

Ideally the nozzle should never, ever touch the print surface. For any reason.

There’s a purpose behind things like the BL Touch having a soft plastic probe on the end.

If you’re bed leveling with a heated nozzle, you’re not doing it right.

Sure, but that doesn’t mean there won’t ever be some situation where it’ll try to Z home for whatever reason, or even if it’s just user forgetfulness, and you poke the PEI sheet with a 215+ degree nozzle. The fact that the mechanism inherently includes that possibility is stupid.

The printer won’t do any leveling with a fully heated nozzle.

The MK4’s we use at work and my personal MK4 all heat up to 170 before bed leveling, and if you previously swapped filaments before leveling, the printer will pause and wait until the nozzle has cooled down to the target range before initiating bed leveling.

Well, then at least they thought of that. Will it Z home with the nozzle preheated? I’ll bet you it will.